Volume Measurement of Conveyor

Production Process Visualization

Inventory Visualization Solution

Automated Tonnage Conversion & Reporting

With a built-in database of 200+ material densities, the system auto-calculates tonnage and generates hourly PDF/Excel reports. It integrates with ERP/WMS for real-time inventory tracking, boosting efficiency 20x and eliminating discrepancies.

All-Weather Millimeter-Level Precision

✔<3mm cross-section error for irregular materials (coal, gravel, etc.)

✔Certified by National Metrology Institutes (NMI)

✔ 24/7 stability in quarries, ports, and steel plants

Aggregate Gradation Real-Time Monitoring System

- 15 FPS 3D Reconstruction

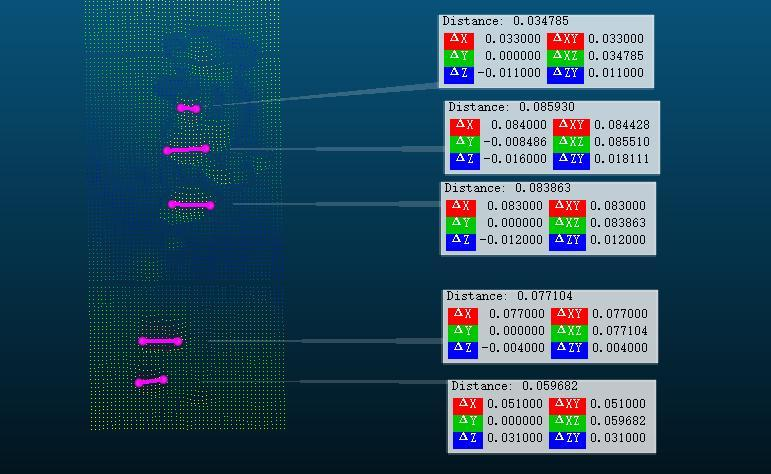

- ±0.5mm Precision

- Instant Over-Size Particle Control

How

How It Works

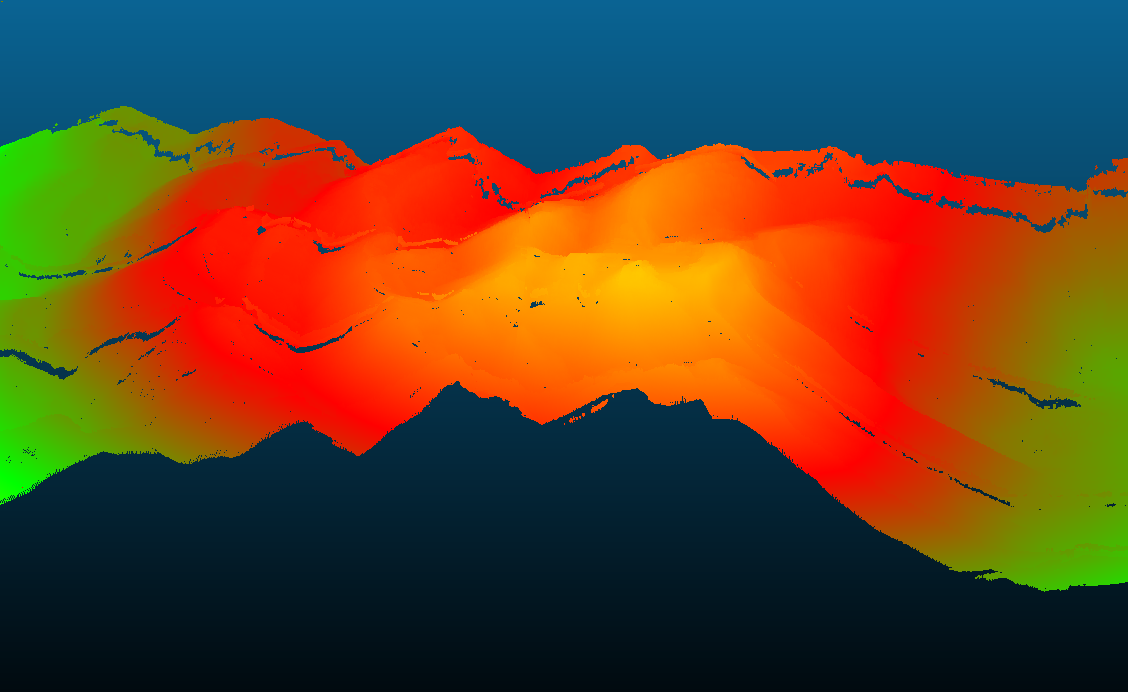

1. Real-Time 3D Scanning: Laser scanners capture 50 cross-section profiles per second Advanced filtering removes dust/steam interference

2. Dynamic Contour Data Capture The Time Synchronization Controller (TDC) locks laser scanning timing with conveyor speed encoder signals, eliminating motion-induced errors and achieving ±1cm³ dynamic volume accuracy.

3. Intelligent Point Cloud Filtering Adaptive algorithms remove dust, mist, and noise, while Gaussian surface fitting restores true material contours. Ensures >99% data accuracy even in PM2.5 >300 environments.

Architecture

System Architecture

Millimeter-Level Industrial Accuracy

Wide-dynamic LiDAR + adaptive point cloud algorithms eliminate conveyor vibration and dust interference.

Zero-Interruption Monitoring

100Hz high-speed scanning synchronizes with conveyor speed for non-contact measurement.

Self-Diagnostic AI Predictive Maintenance

Monitors factors like belt misalignment, material overload, and grading, reducing downtime and improving production efficiency.

Smart Production End-to-End Collaboration

Deep integration with PLC, ERP, and MES systems automatically generates tonnage reports with calorific value and grade, enabling "minute-level" alignment of production and sales data.

Dust and Water Resistance IP67

Tested for cold start at -40°C and continuous operation at 70°C, the IP67 rating ensures protection against high-pressure water jets and PM2.5 fine dust penetration.